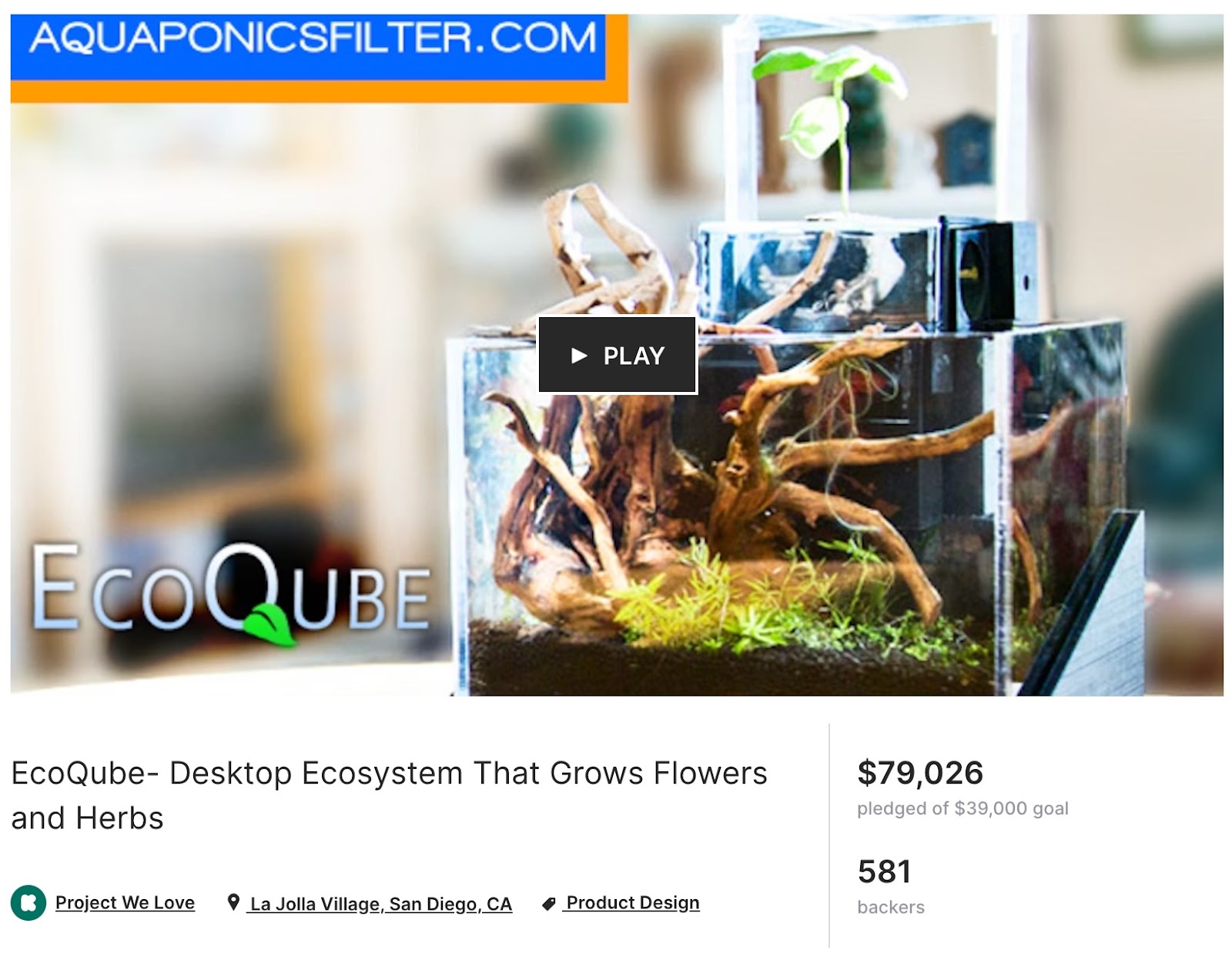

My very first Kickstarter launch raised $79K for my product called the EcoQube. As a first time product creator, I was simply looking to cover the cost of tooling and the first manufacturing run but I was blown away by our success. I had never seen that much money.

But my story of triumph pretty quickly turned into a story of horror once we moved into production. That’s where I made two $100,000 mistakes. This was honestly one of the hardest moments of my life and luckily, I was able to make it through. But I never want to relive it.

This story is not unique to me. Many creators have a successful Kickstarter and then run into major challenges during production and fulfillment that could have been avoided. Even Kickstarter’s own data shows that 9% of “successful” projects fail to deliver. In addition, there are hundreds of other campaigns that deliver years late or products that don’t work. Having gone through this myself many times, my bet is that this is not due to lack of effort, but rather a lack of knowledge and experience.

My hope is that by sharing my story, you can avoid these costly mistakes when it comes to creating your successfully funded Kickstarter project.

Let’s start with $100,000 mistake number one.

Contents

Launching My First Product on Kickstarter

My first Kickstarter campaign was in 2013 with the launch of EcoQube.

Not only was this my first Kickstarter, it was the first time I was manufacturing a product. After the campaign ended, I got the $79,026 (or about $73K after Kickstarter’s fees) wired to my bank account. That was a lot of money to me at the time. But I knew it wouldn’t be in my account for long because I had 581 customers I had to ship my product to.

After interviewing dozens of manufacturers and working with several of them on prototyping, I found a manufacturing partner in China. My engineers and I spent months working with the supplier on designs and samples. They said it would be no problem to produce the EcoQube and like most first time creators, I assumed that just because I had a fully functional prototype, they would be able to replicate and produce it.

I took my first trip to Shenzhen, China, and the day I arrived I realized actually manufacturing a product was much more complicated than I could have ever imagined. I recently heard Elon Musk say in a recent interview with Joe Rogan:

“The hard part, by far, is manufacturing. Manufacturing is somewhere between 100-1000 times harder than making a prototype.”

I wish every first time product creator can get a glimpse into the level of complexity that goes into manufacturing even the most simple products.

I learned that my point of contact is a very reputable factory owner but she was only responsible for the final assembly and quality control. All of the individual parts (there were over 40 parts) were sourced from several independent suppliers and much of the production was actually not under her direct control. Although up until that point she had done a great job of getting satisfactory prototypes and being the middle person, I learned that in order to manufacture the product at scale, I would need to work directly with the suppliers to redesign over 70% of the components for manufacturing. This is after I had hired quite a high caliber engineer in the US to help me with the design for manufacturing!

I spent the entire 2 weeks working day and night with the suppliers to rework nearly all of the 3D models I had previously provided to the suppliers. After I got back home to San Diego, I felt good about the final designs and never had more of an appreciation for the simple things we use day to day. I would look at a simple wall plug and admire it for the curves that allow it to be manufactured but also look natural. I would observe the polish on the plastic and think about the level of precision and sanding that needed to be perfectly executed on the molds.

After the trip, I wired $40,000 from my account. It was half the project’s cost to begin tooling to create all the designs we spent months designing and the 2 weeks re-engineering for manufacturing. We agreed to pay the remaining amount on delivery.

Unfortunately, the first production sample was fraught with issues: a leaking filter, bubbles in the crucial clear plastic in the front of the product and a misshapen filter lid that didn’t fit properly. Driven by anxiety over my significant investment and the commitment to my Kickstarter backers, I flew to China immediately to address these issues.

Trying to fix the issues

Issue #1: A leaky filter

The first issue was a leaky filter, which thankfully was a relatively straightforward issue; it was a matter of thin plastic in the mold. Removing material from the mold to thicken the plastic didn’t require a new mold. I realized this was a typical part of the development process.

If I hadn’t spoken Chinese, I could have easily made up my mind and said the issues were because they’re Chinese and this was the type of work they do. As Americans, the gut reaction can be “What do you mean it’s leaking? You should be fixing it!” but the factory is just involving you in the development. The first sample is the rough draft.

A pile of molds sits in a neighboring injection mold factory that my plastic factory partners with.

A pile of molds sits in a neighboring injection mold factory that my plastic factory partners with.

Issue #2: Bubbles in the plastic

The second problem had to do with bubbles. You see, the EcoQube light was held up by a clear piece of injection molded plastic, bent at a right angle. The plastic had to shoot up through this 90 degree angle in the mold, and so there were always bubbles right in the front of the product.

If the bubbles were always in the same place, we could pass it off as a design feature. But they were always in different places, sometimes on the right, sometimes on the left. It was horrible!

The factory offered to redo the mold, and have the cost split 50/50 (half paid now, half paid later), but I didn’t have the resources to redo the mold. I went back home, did research, and figured out I could cut the mold so there was an extra plastic piece sticking out. Doing this would mean the bubbles would get pushed to this extra piece and could easily be clipped off.

Bubbles in the plastic light support and front of the light.

Bubbles in the plastic light support and front of the light.

This production sample of the EcoQube after I went to China shows the two spots in the front of the light where the plastic was clipped. The extra plastic was added to the mold to prevent bubbles inside the light.

This production sample of the EcoQube after I went to China shows the two spots in the front of the light where the plastic was clipped. The extra plastic was added to the mold to prevent bubbles inside the light.

Issue #3: Poor fitting filter lid

The third hurdle was the filter lid. The frame of the filter lid is black ABS plastic, with a clear (separately molded) polycarbonate piece in the middle to show the waterfall, inside, which reflects the LEDs. I really wanted it. It was beautiful.

The EcoQube filter housing with its clear top lid after the bending issue was fixed, showing off its beautiful waterfall.

The EcoQube filter housing with its clear top lid after the bending issue was fixed, showing off its beautiful waterfall.

However, the polycarbonate warped upon cooling. It bent 2 degrees and led to a poor fit. To make matters worse, the polycarbonate couldn’t be clamped while hot, or else marks were left on it. After a lot of experimentation, I found a solution: After the plastic cooled for 30 seconds (enough to not leave marks when touched), the workers would put it in a rig to clamp it, so that it only bent by 1 degree instead of 2.

The lid with the gap.

The lid with the gap.

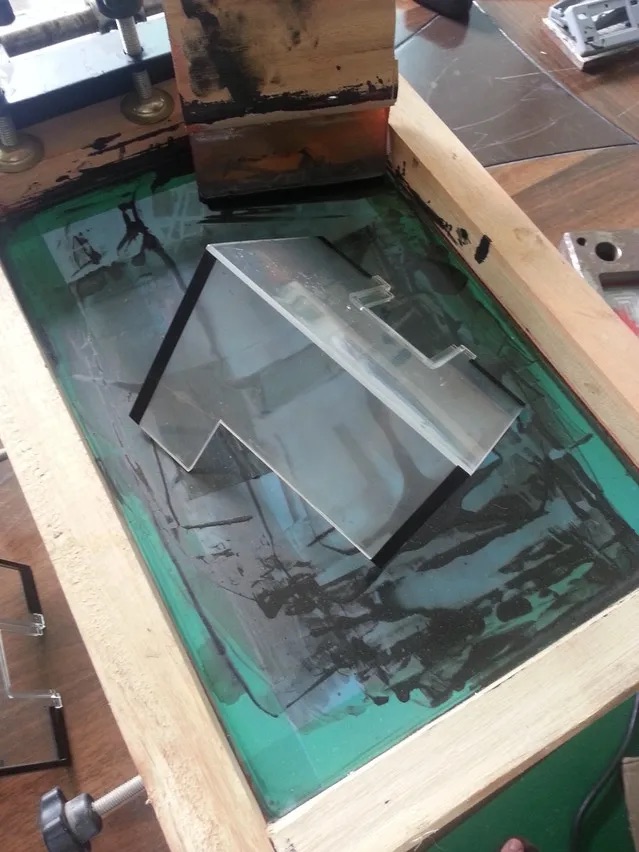

The injection mold for the filter lid.

The injection mold for the filter lid.

One degree was still too malformed for a good fit, so I decided to have the mold altered to add clear pegs on the plastic edge of the lid. The factory workers then used a jig to drill the corresponding peg holes in the frame, and glued the pegs into these holes. Sealing the filter remained a challenge, as using glue was tricky; it tends to leave marks on the plastic if applied anywhere but the seam. The final step to solve this puzzle was to use custom 3M tape, which securely held everything in place.

An attempt to use silkscreen to hide glue marks, which looked really bad, so I ditched the idea.

An attempt to use silkscreen to hide glue marks, which looked really bad, so I ditched the idea.

Here’s the filter lids sealed with 3M tape, undergoing water resistance testing.

Here’s the filter lids sealed with 3M tape, undergoing water resistance testing.

I had to put in a lot of labor since normally injection molded parts come out basically complete, but this extra labor was more cost-effective than making a new mold due to the low volume. In the end, the factory probably produced around 2,000 units in total to achieve 700 units that were satisfactory.

Discovering more issues

Finally, the EcoQubes were shipped to San Diego, where I had rented a section of a warehouse. It was only 650 square feet and could perfectly fit one container right up to where the garage door closed. That’s all we could afford.

Here’s me unloading the container with the help of one of my neighbors.

Here’s me unloading the container with the help of one of my neighbors.

When I inspected the EcoQubes, I realized that a third of them had an issue: The pump was noisy. It’s easy to think, “Oh, they shipped us a defective product.” Nope. Jasmine, the owner of the factory, had tested every single pump before installing it. But once you put it in a confined space, it started making a sound. It was actually a design problem. We had to source new pumps, and I ended up spending my Thanksgiving and Christmas of 2014 with my friends, disassembling the filter, putting in a new pump, testing it to make sure it wasn’t noisy, and then gluing it back together.

Up until this point in my life, I had never gone through more anxiety and stress. My heart rate still shoots up writing this nearly 10 years later.

Left: Unpackaging, testing, and drying before repackaging to rework the filters. Right: Friends helping out with packing at night.

Left: Unpackaging, testing, and drying before repackaging to rework the filters. Right: Friends helping out with packing at night.

Unusable molds

After resolving all of the above and fulfilling all of our obligations, I launched version 2 of the product, the EcoQube C Aquarium. It took all of the learnings above and applied it to a brand new design that made the product better for the customer and made our manufacturing process more nimble. This allowed for faster iterations on designs and hardware upgrades using acrylic sheets which did not require reworking injection molds.

4 months after the delivery of the very first EcoQube Aquarium (the one shown above), I launched the EcoQube C in April 2015 and it was wildly successful raising $375,000. It is still the most funded aquarium in crowdfunding today. In 2 months, the EcoQube sold 10x the volume of the total first EcoQube sales and we never used the molds we worked so hard on ever again. I had spent 2 years of my life designing the product, working with mold engineers to navigate the challenges you read about above only to never use those expensive molds again. The molds were made with extremely high quality steel and could handle 200,000 “shots” using those molds but we made and shipped less than 1000 units. On the other hand, we produced and shipped nearly 100,000 EcoQube C Aquariums from 2015-2019.

I wish someone could have told me before I paid for those molds.

My manufacturing lessons learned

I have three big lessons I learned from this experience:

- Manufacturing any product will be 100-1000x harder than making a fully functional prototype. Despite what you may think about Elon, I recommend listening to him here.

- Invest the time, money and energy in identifying and developing a real relationship with an outstanding manufacturing partner. I don’t think I would have been able to pull this off even with a “good” partner. I was VERY fortunate that despite the lower volume and my lack of experience, our partner, Jasmine stuck it out with me in resolving these issues the entire way. No matter how perfect your plan is, something is bound to go sideways in sourcing and manufacturing. You need an outstanding partner next to you to navigate the unexpected.

- Have someone on your team who has gone through this full journey working with you side by side or checking in with you during each of the steps advising you. I had a very senior engineer helping me build prototypes but he wasn’t there with me when I was completing the manufacturing. I had an incredible manufacturing partner that went above and beyond to help me navigate everything above but was not there with me in the design process to really question whether or not tooling up to injection mold all the parts was really necessary. That would’ve saved me $100,000. I had a logistics company but no one helped me identify the correct strategy around mitigating duties, tariffs and fulfillment. That would’ve saved me an additional $100,000 but that’s a story for another time.

Launching your product through Kickstarter or Indiegogo is exciting. But making mistakes like mine can quickly make that excitement disappear. Learn from my mistakes so that you don’t have to make them.